From base materials to mission-critical engine components, Off Site delivers tight-tolerance parts that keep your production lines—and your reputation—running strong.

Many foundries pour world-class castings but lack the CNC milling, balancing stations, or coating lines to finish them. Off Site acts as your off-site production line, turning raw castings into plug-and-play components while you keep the melt deck hot.

Typical Parts:

Value to you:

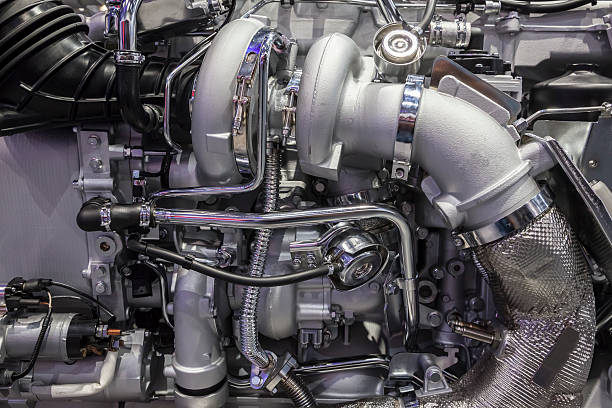

Torque, vibration, and million-mile duty cycles demand exceptional accuracy. Our crank pulleys, tensioner assemblies, and fan bases help global truck OEMs hit durability targets without costly rework.

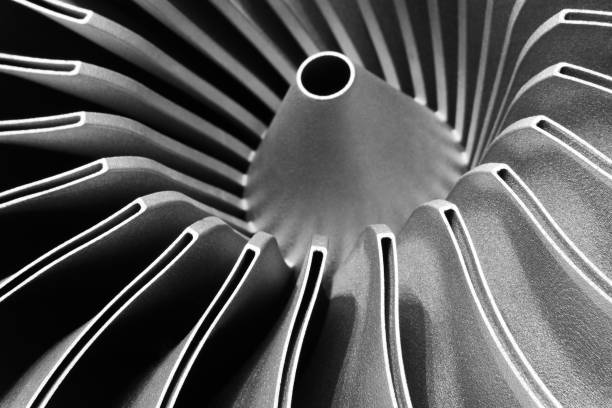

Off Site’s audit-ready quality system and secure logistics mean critical parts—fan hubs, bracket assemblies, APU components—arrive on spec and on schedule for DoD contractors and depots.

We micro-finish pump housings and balance rotor assemblies that endure extreme temperature swings and high cycle counts in ground-support equipment.

Bearing journals, brackets, and pulleys are machined, coated, and laser-ID-marked, helping Tier-1 suppliers hit PPAP gates with fewer vendors.

0 line stoppages attributed to Off Site parts in 5 years

Flexible robotic cells for rapid changeover & surge capacity

© 2025 Off Site Manufacturing. All rights reserved. | Web published by Marketing Options, LLC. | Terms & Conditions | Privacy